DATE FROM 1985

Professional manufacturer of Thin wall Mould

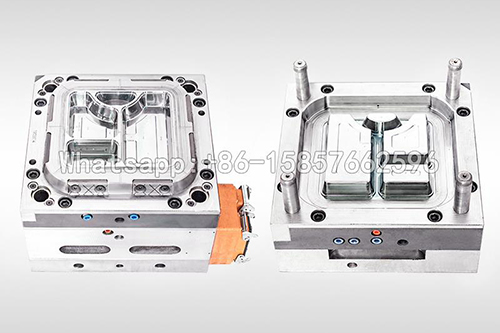

Points of Manufacturing Thin Wall Food Container Mould

With the progress of the social age and the liberation of human labor, our time is becoming more and more precious. The takeaway market is booming. The demand for fast food boxes used for takeaway grows exponentially, and the thin wall food container mould market is born. Guoguang Mould has rich experience in the production of thin wall food container moulds. We can produce high-quality thin wall food container moulds according to product design and mould design.

Since 1985, we have maintained an annual shipment of 60 sets of thin wall moulds. Thin wall mould have been shipped from one to eight-cavity moulds. As the number of mould cavities increases, the moulds are getting higher and higher. So how to choose a high-quality food container mould?

- First, you need to choose the appropriate product specifications and shapes: the current market shapes include round and rectangular shapes. The conventional capacities are 500ml, 750ml, and 1000ml. The rounded products are slightly lighter than the square ones. The most important factor for thin wall food container moulds is the thickness. The thinner the product, the better, because it may increase the cost of materials and the production cycle

- The second point is the selection of the mould material: because the thickness of the thin wall mould is only 0.4-0.8mm, the injection moulding machine adopts a high-speed injection moulding machine, and the mould needs to withstand high pressure, so the thin wall mould needs high-hardness steel to prevent the mould Under the long-term high-speed and high-pressure mould deformation, the product flashes and increases the cost.

- The third point, mould design: Guoguang mould has 50 excellent professional design teams, thin-wall mould design needs to consider the following points: product parting surface, product wall thickness design, mould exhaust design, mould waterway design , Mold blowing position and direction design, these problems directly determine the success or failure of a thin wall mould.

- Fourth, the mould needs to achieve fully automatic production: thin wall products are an industry with small profits but quick turnover. The thin wall food container mould manufactured by our company can achieve 5s automatic production. Equipped with a robot can produce and run faster, and the robot can help you directly After the stacking is completed, the belt will be directly packaged and shipped.

- Fifth point: In a short cycle time, our designers will analyze the product according to customer requirements, and then try to find the best cooling water path for the mould. Our technical team developed a high-speed injection moulding thin wall container characterized by a 4-cavity mould with a thickness of 0.35mm, 0.5L, and a period of 3.5S.

- Sixth point: We can provide IML technology according to customer requirements,

If you are looking for a thin wall food container mould supplier, please contact us, we can not only help you produce thin wall food container moulds, but also provide you with related production solutions. When the thin wall food container mould and equipment meet the customer's requirements and start production, we will provide you with technical support to ensure that your production goes smoothly.