Professional design team

1. The group mode implements strict 6S management standards, accurately communicates assigned tasks, and immediately follows the refresh task process

2. Unique standardized design process and design standards provide faster speed and higher quality for mold design

3. Project communication management and file transfer through professional tools, giving the most secure storage environment for files

4. Streamlined mold design process to ensure that the most professional employees work in their areas of expertise

5. Provide clear, high-quality 2D processing drawings for on-site processing, quantifiable planning and testing of component structural dimension tolerance drawings for quality and processing, order standard parts that meet product standards, and ultimately provide customers with detailed and complete mold transfer information.

Quality certification

At present, the company's quality management system has passed the certification of ISO9001: 2015, IATF16949 and VDA6.4 and other system standards. The quality management system is fully extended to the company's various levels with the quality assurance department as the center.

Physical inspection

Monitor the quality of the mould process and the inspection before the mould test. Supported by rich and effective measuring equipment resources and human resources, control every size and problem of the mould to ensure that the mould shipment rate is 100%.

Project Engineer

Participate in supporting customer's product design, and conduct feasibility analysis of product and mould structure, remove problems in the early stage, save time and cost and improve quality for mould design and processing.

Raw material monitoring

Raw material monitoring is a crucial step in quality control. Controlling the inflow of unqualified raw materials can avoid the quality problems of the mould itself from the source, and strictly control the quality of all kinds of mould raw materials to the factory for acceptance.

Full service

We are always convinced that what shows the high end in the details is the demand for the ultimate quality service of the mould,Technology shows strength and quality wins trust.

Mould Design

Zhejiang Taizhou Guoguang Mould Plastic Co.,Ltd. unique standardized design process and design standards provide faster speed and higher quality for mould design

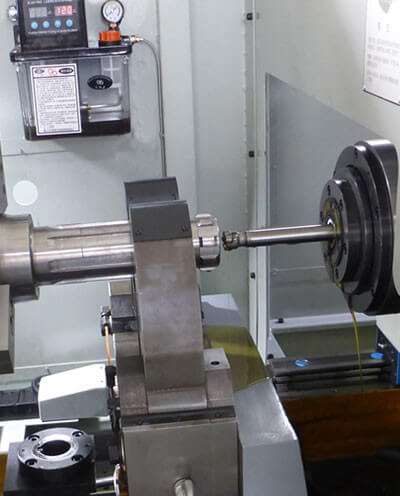

Mould Machining

Finishing raw materials through machine tools. We have experienced engineers responsible for material selection and analysis.

Mould Clamping

And understand the relationship and function of each part, its characteristics and technical requirements, coordination requirements and connection methods.

Porduct injection

We have detailed process descriptions on materials, machines, mould preparation, etc. Sampling inspection of mold installation, mold opening and closing, and parameter setting adjustment was carried out.